SkinPaper: Exploring Opportunities for Woven Paper as a Wearable Material for On-Skin Interactions

SkinPaper: Exploring Opportunities for Woven Paper as a Wearable Material for On-Skin Interactions

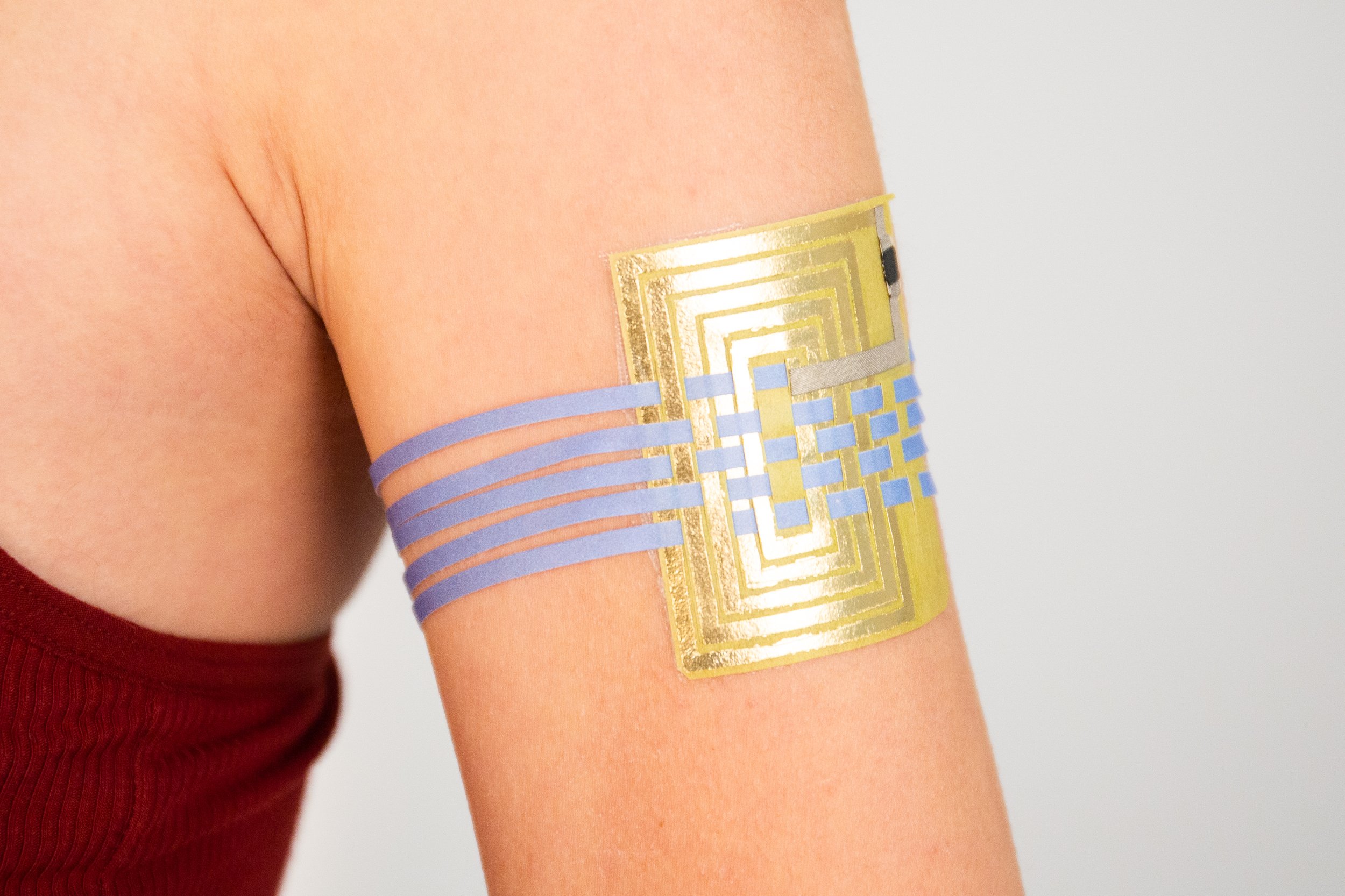

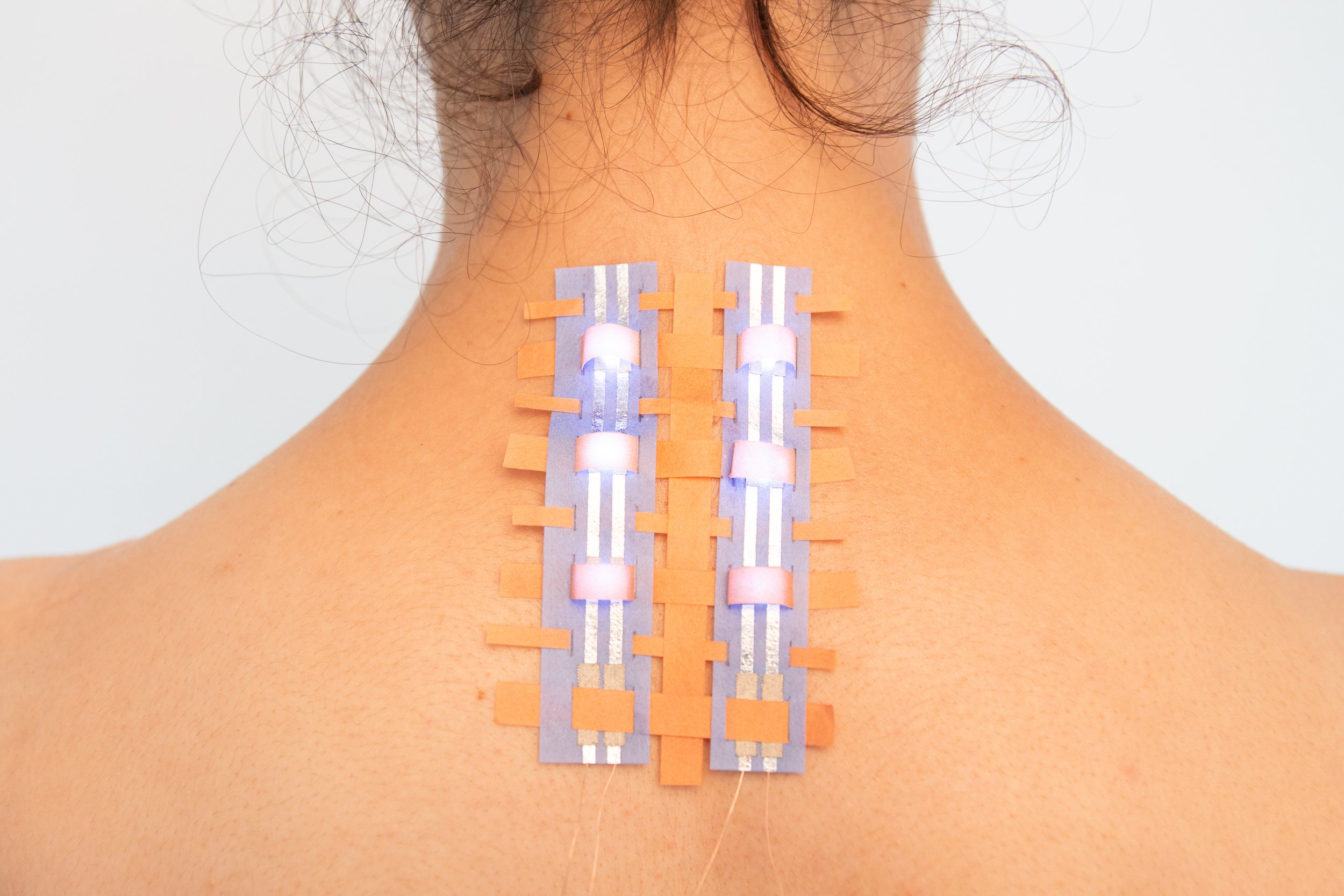

We present SkinPaper, a fabrication approach using silicone-treated washi paper to weave lightweight and easy-to-fabricate on-skin interactions.

Paper circuitry has been extensively explored by HCI researchers as a means of creating interactive objects. However, these approaches focus on creating desktop or handheld objects, and paper as a wearable material remains under-explored. We present SkinPaper, a fabrication approach using silicone-treated washi paper to weave lightweight and easy-to-fabricate on-skin interactions. We adopt techniques from paper weaving and basketry weaving practices to create paper-woven structures that can conform to the body. Our approach uses off-the-shelf materials to facilitate a highly customizable fabrication process. We showcase eight case studies to illustrate our approach’s two to three-dimensional forms. To understand the expressiveness of the design space, we conducted a workshop study in which weavers created paper-woven on-skin interactions. We draw insights from the studies to understand the opportunities for paper-woven on-skin interactions.

Publication:

SkinPaper: Exploring Opportunities for Woven Paper as a Wearable Material for On-Skin Interactions

Jingwen Zhu, Nadine El Nesr*, Nola Rettenmaier*, and Cindy Hsin-Liu Kao (*equal contribution) Proceedings of the 2023 CHI Conference on Human Factors in Computing Systems (CHI ’23), April 23– 28, 2023, Hamburg, Germany. PDF | DOI | Project Page

Project Credits: Hybrid Body Lab at Cornell University, directed by Cindy Hsin-Liu Kao

Research Team: Jingwen Zhu (Lead Researcher), Nadine El Nesr, Nola Rettenmaier, Prof. Cindy Hsin-Liu Kao (Lab Director)

Press Inquiries: Press Image Kit: Download Here (License: CC by-NC-SA 4.0) Press Contact: Prof. Dr. Cindy Hsin-Liu Kao, cindykao@cornell.edu

THIS PROJECT WAS SUPPORTED BY NSF UNDER GRANT IIS#2047249

We present SkinPaper, a paper-woven fabrication technique us- ing silicone-treated water-repellent washi paper to rapidly prototype on-skin interfaces. Washi paper’s cross-cultural familiarity through time and its material and structural properties make it an attractive conduit for the goals of this research. As a readily available and accessible crafting material, the nature of crafting with paper can be less intimidating. It could open the field of on-skin interface fabrication to a broader audience, empowering more diverse populations to take part in co-defining this new technology. Furthermore, because washi paper is previously untreated (unlike standard printer paper), its cellulose fibers are easily accessible to chemical treatments, making it a good material choice for water-repellent and resilient on-skin wearables. In addition, the rich materiality of washi paper enhances the affordance of on-skin interfaces by expanding its physical properties and expressive dimensions. The paper-woven fabrication approach extends weaving techniques to create interfaces with unique textures and three-dimensional structures without requiring specialized tools or machinery.

We defned a twofold design space consisting of (A) Paper Primitive Elements and (B) Woven Structuring Techniques to create SkinPaper Interfaces.

The primitive paper archi- tecture for on-skin interfaces is a multi-layer structure. It consists of four layers: the base washi paper layer, the design layer, the hydrophobic layer, and the interaction layer.

We synthesized the Woven Paper Structure Design Space affords 2D patterns, 2.5D textures and 3D structures.

We present a total of 8 case studies generated through our research through design methodology to explore design opportunities for paper-based on-skin interfaces. These explorations offer insights into the creative capabilities of the SkinPaper design space, providing generalizable design solutions for future SkinPaper applications. We present case studies of each paper weaving structural dimension: first examining three case studies of 2D patterns, three case studies of 2.5D textures, and two studies of 3D structures that can directly envelop body locations.

We conducted a design workshop study with four participants to understand end-users’ iterative design process from low- to high-fidelity prototyping. We aim to observe the feasibility of rapidly creating a low-fidelity prototype using SkinPaper, to the "high ceiling" and "wide walls" potential of SkinPaper’s design affordance. We also aim to discover how individuals with diverse weaving experiences adapt this new fabrication approach to their practices.

Participant's project: a 3D shoulder warmer for easing shoulder pain woven on a floor loom. (Image Credit: Hybrid Body Lab) (License: CC BY-NC-SA 4.0)

Participant's project: a 2.5D touch-triggered bracelet using basketry weaving techniques. (Image Credit: Hybrid Body Lab) (License: CC BY-NC-SA 4.0)

Participant's project: a 3D hexagon weave touch sensing harness triggers different tones. (Image Credit: Hybrid Body Lab) (License: CC BY-NC-SA 4.0)

Acknowledgements:

We thank Pin-Sung Ku and Heather Kim for their suggestions and input, Xia Zeng for technical support, and Chi-Jung Lee and Nancy Wang for modeling photos.